For pharmaceutical companies like Bristol Myers Squibb, the biomanufacturing process of biologic drugs presents challenges to process scale-up.

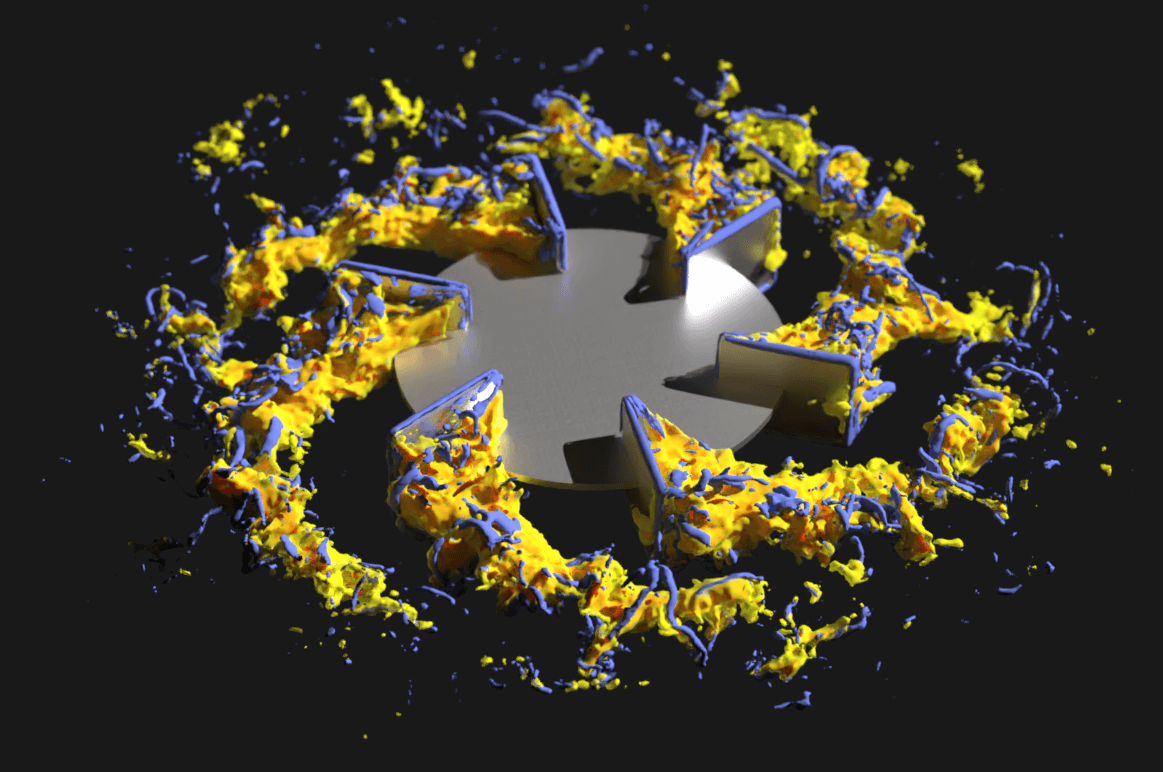

“The better we understand what’s going on in a bioreactor, the better we can scale processes up, the more yield we can get, [and] the more easily we can transfer these technologies to other contract manufacturing organizations,” said M-Star CFD President John Thomas, PhD.

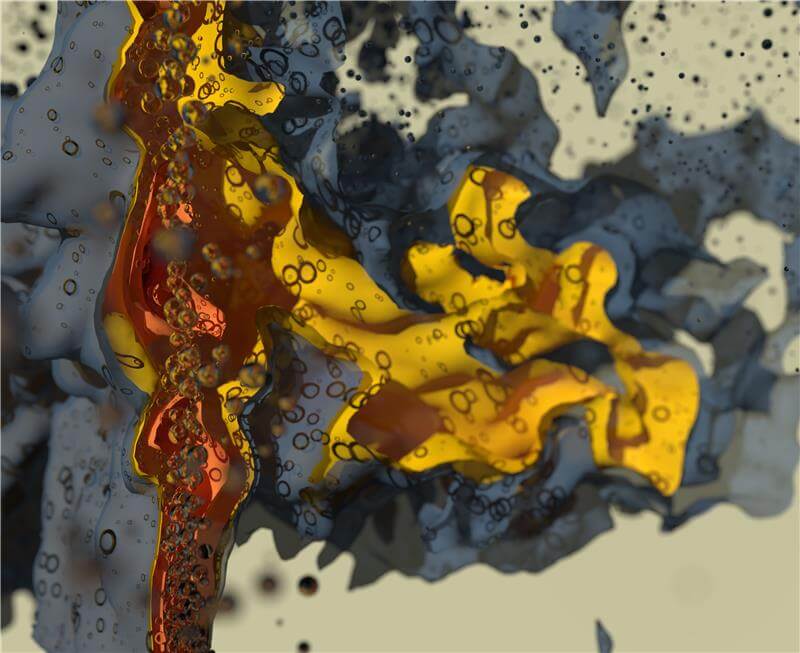

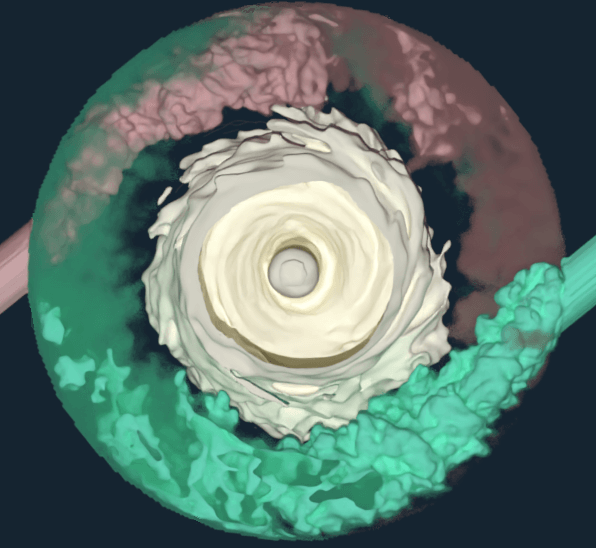

Unfortunately, the complex fluid mechanics at play make traditional predictive mathematical modeling slow and difficult.

That’s why BMS turned to M-Star’s next-gen GPU-native CFD software.

“What’s neat here is that we can develop a mechanistic model for predicting such a wide range of bioreactor operating conditions,” said Thomas. This approach helps BMS speed up the production timeline and reduce the costs of biologics production, so they can get the compounds to market faster.

To learn more about the approach and results, read the full case study—and watch the video below!

Explore the Scientific R&D Software

Explore the Scientific R&D Software