“The ability to understand what you’re expecting out of the tool helps you inform whether or not you’re getting reasonable answers. But I think getting your hands dirty and understanding the tool you’re using is important to know what inputs you need to get good answers out.”

– Eric Janz

This week, guest Eric Janz, Faculty of Practice at University of Dayton Innovation Center, joins John to discuss his experience with CFD and to address a frequently asked question: Do you need a PhD to run information from a CFD simulation?

In this episode, John and Eric talk about:

- The acceleration of CFD over the past 25 years in industry and academia

- Traits and skills of successful simulators

- Advice for people who want to get good at CFD

John Thomas: So we’re talking today about credentials and what kind of skills and formal training and background you need to run CFD. And we’re trying to answer the simple question: Do you need a Ph.D. to run information from a CFD simulation?

So to help answer this question, I’ve invited Eric Janz, a Faculty of the Practice at University of Dayton Innovation Center, to discuss his experience with CFD and how he sees it being used in industry and academia. Eric, thanks so much for being here to discuss this topic.

Eric Janz: Absolutely.

John Thomas: So Eric, for folks who may not know you, introduce yourself briefly. Tell me a bit about your academic trajectory, your professional trajectory and how you got to today.

Eric Janz: Yeah, I graduated from University of Dayton with an undergrad degree in chemical engineering, went back immediately and got a master’s degree in chemical engineering. And that’s where I started some of the CFD work – this was mid-nineties – and did some work with Fluent back then.

And then as I worked through my career, I started at Chemineer, making industrial mixing equipment kind of straddling the line between the sales and the research and development end of things for the first ten or so years of my career, working in the application side and in the development side, and then worked through the engineering end of things and then wound up for the last ten or so years of my career fully in the research, development and innovation side at Chemineer.

And in the last five or so years, I’ve transitioned into an academic role here at the University of Dayton, and the CFD piece has been something that I’ve used to complement the experimental portion of the work we did and within that end of things on the development side.

John Thomas: So you said you started doing this analysis and CFD analysis in the nineties. It’s kind of shocking for me to say right now that the nineties were 25 years ago. I still can’t get used to that. That’s a long career of using these types of tools. You must have seen a lot of change in those past 25 years or so of doing CFD simulation.

Eric Janz: Yes, when I first started doing some of this, the sliding mesh end of things on the 3D simulations was just getting started. All of the CFD work we were doing was on Unix, not Linux, Unix workstations, and the start there was very interesting to kind of see where a lot of the initial simulation work and where it’s come from, what you could do then and you could do now.

When we were starting out with some of the automated CFD tools that we used, we were pulling information in from the design systems to design the agitators. And you were using all the symmetry you could using patched boundary conditions to take a look at the flow fields. So you were taking a look at a 2D simulation piece and the runtime was for hours to get that work done, and it was impressive results for the mid-nineties.

John Thomas: Mm-Hmm.

Eric Janz: Contrast that to what you can get done in those three hours today on some of the computational resources that are available, even to general practitioners. It’s really almost mind-boggling the difference between what you can do today and what you could do 25 years ago.

John Thomas: I know the topic of discussion is supposed to be, you know, what sort of credentials you need to use CFD. But I’m just fascinated by your perspective.

So just briefly, if you look back over these 25 years, are there a couple of punctuations you see where you’re like, “Oh, today is different now than it was before because this change happened,” or “Oh, that’s a new functionality that is going to change the way I want to use this type of analysis.” Just because you have the perspective, do you remember any of those punctuations over the last 25 years that anything stood out to you or is it a bit more of a kind of a gradual maturation of the technology?

Eric Janz: Hmm. That’s a good question. A lot of the development in the last ten or fifteen years after I got started was more of that gradual feature additions. The sliding mesh implementations got better, meshing got faster. You were taking advantage of being able to use more CPUs to get things done, so the size of the jobs increased, probably in the 2005 to 2010 range, when you were really able to start running meaningful simulations on PCs that you could do development work on.

The development work, it was interesting, I think from a Chemineer standpoint, one of the biggest impacts was when you could actually do work that would impact some of the job end of things. So being able to do simulations that were customer-specific and were timely enough to be able to impact a sales cycle.

John Thomas: Right.

Eric Janz: So then that started happening more as you moved into that 2005, 2010 range.

John Thomas: Mm hmm.

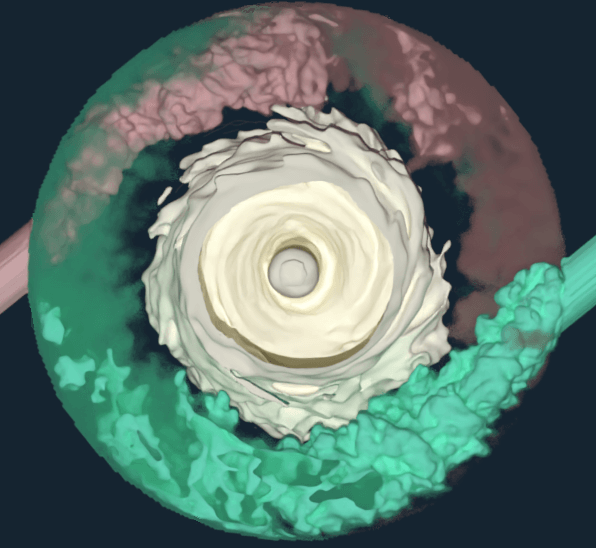

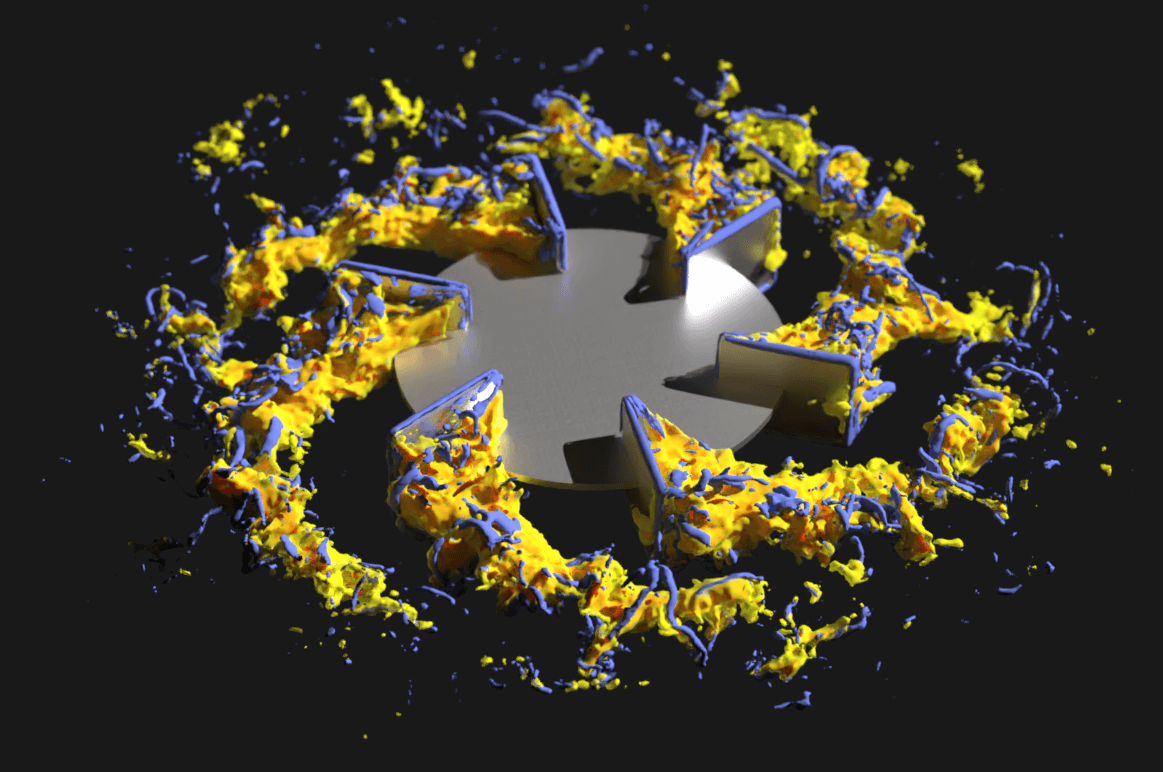

Eric Janz: The next big change with the way we did things at Chemineer was when we started working with you at M-Star. Where really we’re able to move from some of the averaging techniques that you had in most of the RANS-based simulations and we started being able to use the large eddy simulations on a more consistent basis and to get results. Chemineer has the Kinecs Static Mixer line in there, and one of the things that we used the M-Star tool on was some of the static mixer development, especially on the turbulent side, because taking a look at how an average flow field looks to get at some of the mixing in short distances on some of the turbulent mixers where you may need mixing in a diameter or three diameters is a lot more challenging than using some of the averaging techniques for things that have longer resonance times.

John Thomas: Yeah, yeah.

Eric Janz: So that was one of the really big first places that we were able to use the large eddy simulations to make an impact in the business there.

And then in you know, in the last couple of years, as the GPU technologies have really emerged, the ability to take that work that would take you tens or hundreds of CPUs in a cluster and be able to do that on one or a handful of GPUs really makes a big difference in what you can get accomplished now. And I think that those step changes here in the last five, eight years have really been big changes and what you can get accomplished in an industrial time scale, something where you’re looking for answers on the order of hours or days, not the weeks to months type of timeframes.

John Thomas: Right, yeah, it’s a good retrospective. I think it’s neat to be able to kind of point to events and changes that really had an impact on your industrial workflow. So it sounds like you kind of developed your career in parallel with the emergence of these new algorithms and approaches for doing CFD. You know, when you’re coming out of college, were you trained on CFD or is this something you had to learn on the fly?

Eric Janz: This is something I learned on the fly in grad school. We did some work on optimization techniques. We did some of the statistical thermo where you got into understanding some of the simulation pieces. But in my educational background, I didn’t get any pure CFD.

John Thomas: Yeah.

Eric Janz: My initial mentor on the CFD side was Andre Bakker, who worked at Chemineer from the early nineties through the late nineties, and he’s really a pioneer in a lot of the application of this type of work. And then he went and moved back into Fluent at the time before it became Ansys, but that was the introduction I had.

There was the training on the job. Here’s a firehose. Here’s a tool. It’s neat. And you know, some of that was my interest in learning some of that, and some of that was just the business need to be able to turn the simulations and figure out how to get that done and be able to start applying that, especially on the application side.

John Thomas: So after 25 years of doing this, clearly doing something right to kind of keep yourself busy for that long, I’m sure you’ve seen some people kind of come and go from simulation.

What do you see in the people that really stick and get information out of it, get utility out of these simulations? What sort of traits or skills or kind of unifying themes do those folks tend to have? It’s not for everybody, right? Some people, you know, don’t really latch on to simulations. Do you see any traits that lead towards really gravitating towards this type of analysis and succeeding in this type of space?

Eric Janz: Well, there’s a, I think, a couple of different categories I’ve noticed or seen as I’ve moved through, and one is the academic where you’ve got very detailed understanding of the process and what needs to happen and how all of the underpinnings work. And especially early in my career, that was not the case. It was a tool to be used and I think for where I’ve come from and used it, using CFD as a tool has been very important. And part of that is just being at an industrial equipment manufacturer. It’s not like we’re at one of the major chemical companies and we’ve got a specific process that we can tune a simulation for and then take a look at variations on a theme and any of the equipment manufacturers, you’re dealing with folks from water treatment, high-end chemicals and pharmaceuticals, and the application range is dramatic. And what you want to get out of the simulations or the experiment or whatever you’re doing can be pretty different. So you don’t have the time to be able to develop a specific model for a specific application. You need to be able to pick up a tool and know where you can use it.

And so from that standpoint, that’s kind of where I see the difference. You’ve got the folks that can use the tool to get the answer and to understand where the limitations are in the tools that you’re using. You don’t want to overreach and make claims that aren’t supported by what you’re doing because it’s very easy to get pretty pictures that support the answer you want without being able to have the actual support for the answer that you need to get.

And then on the other side, you’ve got the folks that have that really deep understanding of the particular niche they’re in. So from a gas dispersion standpoint, if you’re using some of the whichever models that you’re using, being able to tune that to the spot that you need to, to be able to get the power draw or the mass transfer, the hold up, those types of things are important to be able to do and can be very useful in specific applications. But in the experience I’ve had and the spots where it’s been most useful has been when you can pick it up, use it for that thing you need as a direct replacement for experimentation. Have trust that you’re getting a reasonable answer and then you can move on.

John Thomas: Some folks need these tools in a way a handyman needs his truck, right. He can take it anywhere and solve almost any problem, but he needs to act fast and know how we can use his tools to solve a variety of problems. Some folks, you know, go to work in a production facility or plant where they’re using the same piece of equipment over and over and over again. But they need to know the ins and outs and particulars of it to make sure they’re delivering a consistent product. So seems to me like a skill set you need to run these simulations well is somewhat informed by the type of work you’re doing, right?

Eric Janz: Mm-Hmm.

John Thomas: But it sounds like the recurring theme here might be understanding the science, understanding the physics enough to know when an answer is right and when it might be wrong, if I’m reading between the lines correctly.

Eric Janz: Yes, some of that’s experience-based – with any of the simulation things you need to have a good idea of what the right answer should be.

John Thomas: Yeah.

Eric Janz: You get yourself into big trouble if you’re blindly trusting results of whatever you’re doing. I’ve gotten myself into trouble then on the simulation side, but on the experimental side as well.

John Thomas: Yeah, no, that’s a really astute comment. You got to have some idea of what you should be getting. And that actually kind of might answer some of our initial question, do you need a Ph.D.? It might not hurt, but it’s not going to help you if you still don’t have an idea of what at least is physically realistic, realizable in your systems, right?

Eric Janz: Right. Yeah, absolutely.

John Thomas: So let’s say you have somebody that wants to get good at CFD. I mean, what would you encourage them to do? Is it just keep practicing it? Is it to go in the lab and go to experiment? I mean, I know I’m being facetious there, but what would your counsel be if someone wants to get familiar with using these tools and applying them to real industrial problems?

Eric Janz: The route I took is similar to what you’re talking about there, where I had a significant advantage of being able to see both the experimental side coming through an industrial manufacturing facility where you get to see all sorts of different applications.

So the ability to understand what you’re expecting out of the tool helps you inform whether or not you’re getting reasonable answers. But I think getting your hands dirty and understanding the tool you’re using is important to know what inputs you need to get good answers out, depending on the sophistication of a customer.

On the application side, you may have someone who has the rheology information, by temperature, by sheer rate, by concentration and then sometimes you get someone who tells you it’s kind of like mayonnaise, but maybe with some molasses in it or something. You get some variations in what that input is.

But the input into any of these systems is very important in getting reasonable outputs out. But I think the way I did it, and I think it makes some sense, is that you start simple. Make sure that you understand the tool so you can get good, consistent answers and then you start building some of the complexity of the work that you do. And that’s similar to a lot of the training that you get on a lot of jobs.

Also, I think having the ability to take some risks and to have some failures, to understand that not everything works, and understanding where the failure points are, where you get into trouble, is as valuable as, or more valuable in a lot of cases, as being able to get that success. Kind of that fail fast, fail forward kind of mentality to getting up and running in these things.

John Thomas: Yeah. And that’s one of the advantages of simulation is that if you’re just playing around and testing, the stakes aren’t high, right, you can fail. You can restart. You are never more than a “control z” away from where you started. And I think that and recognizing that, I think, is one of the key steps to becoming a good simulator. If you’re willing to test, break, play and restart until you understand the tool well enough to apply it to a variety of circumstances and have confidence in what it’s predicting.

Eric, this is great. I really appreciate your perspective on these problems. I guess it’s not often we get to talk to somebody that’s been doing this, you know, this might sound intimidating, in four different decades, right?

Eric Janz: Thanks. I had not looked at it that way before. [Laughs]

John Thomas: And here’s to many more. But I appreciate your perspective and some of your comments here.

And so I guess to answer the question, what sort of credentials do we need? What sort of degrees do we need? Do we need a Ph.D. to run CFD? I don’t think so. I think it’s the wrong question to ask. Well, what we need to run CFD is some familiarity with the physics. Some familiarity mechanisms and some familiarity with what we expect the physical result to be. I think having those insights intuitions in tow are probably the most relevant set of skills you might have as you go and tackle a modeling challenge. If I try to surmise some of your discussion there.

Eric Janz: Yep, that sounds good.

John Thomas: So if people want to connect with you, is there a good way for them to reach out Eric? Are you on LinkedIn or can they access you through a faculty page at University of Dayton?

Eric Janz: Yeah, I’m on LinkedIn, faculty page at the University of Dayton as well.

John Thomas: Great Eric, we’ll put your contact information in the description below. Thanks again for being here and sharing some of your perspectives with us there.

Eric Janz: Yeah, thanks for having me. I appreciate it.

Get in touch with Eric Janz on LinkedIn or through the University of Dayton.

Explore the Scientific R&D Software

Explore the Scientific R&D Software