This week, guest Piero Armenante, Distinguished Professor of Chemical Engineering at NJIT, joins John to talk about his background in mixing, what it takes to join his research group at NJIT, and the hybridization of CFD and experiment in his research.

“In general, going for your PhD is an exercise in frustration. I told the students ahead of the game. So essentially, you bang your head against the wall 1000 times, but you keep doing it until you’re able to crack the wall, so to speak, and be able to make a dent—and that happens all the time.”

– Piero Armentante

In this episode, John and Piero discuss:

- The importance of hybridizing CFD and experiment in research

- Perspective on future software needs for the CFD community

- Challenges with complex rheologies

John Thomas:

Hello, everybody. Welcome to the CFD mixtape. Today we have the pleasure of speaking with Piero Armenante, a distinguished professor of chemical engineering from the New Jersey Institute of Technology. Piero, thank you so much for being here today and joining us on the podcast.

Piero Armenante:

Thank you for inviting me, John.

John Thomas:

So, Piero, we’ve crossed paths quite a bit over the past few years.

Piero Armenante:

Yes.

John Thomas:

I know you’re a chemical engineering professor. I know you’re NJIT. I read a lot of your papers. Tell me more about your research area and some of your research expertise.

Piero Armenante:

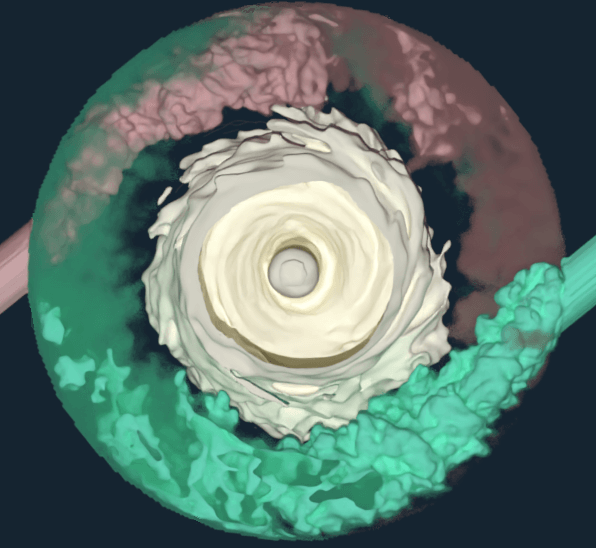

Sure. I’ll be glad to do that. Well, I’ve been involved in mixing for quite some time. And one has somehow to define what one means by mixing.

John Thomas:

Mhhmm.

Piero Armenante:

There are many definitions, of course, so historically this has been associated with essentially stirred tanks. And in fact, this is one of the main activities that has been associated with mixing in general and including my work. But as far as I’m concerned, we have extended that kind of work to examine a number of different systems so that we can have a better idea of the impact of some of the fundamental […] properties or characteristics of the system we look at.

John Thomas:

Got it.

Piero Armenante:

So of course, a lot of this work has been done and also mixing of stirred vessels. But that’s not always the case. I’ve done quite a bit of work actually in environmental area at the beginning of my career, then I moved on to other interests. But mixing has always been there one way or the other.

John Thomas:

I’ve only known you as someone that has expertise in understanding processes that is, you know, biopharmaceutical process, et cetera. You did environmental work early in your career?

Piero Armenante:

Yes, yes.

John Thomas:

Tell me about that; I didn’t know you were in that space.

Piero Armenante:

[Laughs] Well, yes, it was environmental work, but I kind of lived a double life at that point because environmental work was more related to biological treatment of wastes. And so I collaborated with the microbiologists and a lot of that work actually is an interface between microbiology and chemical engineering. So that utilization of these microbiological tools primarily microorganisms to be used in reactors of different shapes and kinds.

John Thomas:

Got it, got it.

Piero Armenante:

Also stirred tanks. But in those days, at least because the typical processing involved in microbiological degradation of waste takes a long time, usually stirred vessel is not necessarily the best system. So we look at a variety of different systems, including stirred vessels.

John Thomas:

Got it. And so I understand now a bit of this common thread from somewhat of the waste treatment industry and the biologics associated with it into more of the pharmaceutical industry. I see kind of the thread here between those two.

Piero Armenante:

Oh yeah, actually, pharmaceuticals have always been there […] my work must be supported by a pharmaceutical company and the like. So my interest in the pharmaceutical processing area has always been there. Even before the environmental interests.

John Thomas:

As the professor and the leader of a research group, what I’ve always liked about kind of what’s coming out of your lab is the hybridization between experiment and simulation. And there aren’t many groups, I think, hybridized and kind of bridge that space as well as yours. How did you create that environment and cultivate that space where again, simulation and experiments shake hands?

Piero Armenante:

Sure. Well, I always thought that, first of all, my personal interests were always on both fronts, but I started as an experimentalist, quite frankly. So that’s always been the starting point for me. And especially going back to environmental work, then that definitely needs some heavy duty experimental kind of activities, which are, however, also combined with some modeling interestingly enough. As far as mixing in general is concerned, I always started with some kind of experimental system that I was looking at. But I also realized, some time ago, that it would be very interesting to integrate whatever we were observing in the lab in experiments also with the ability to kind of reproduce in silico what we were doing. So I thought that this was always a very powerful combination of things, and I tried the best I could to have my students not just focus on one aspect, meaning experimental or computation, but always expose them to both.

And in fact, I have some great success stories with some of them that did a fantastic job on both sides. Most of them, in most cases they started as experimentalists, working on experiments, mixing experiments, and I really forced them sometimes because they didn’t want to go in that direction to also do some modeling to replicate what they were seeing at least some aspects of the experiments.

John Thomas:

Yeah, that makes a lot of sense.

Piero Armenante:

And we expect extended that also to systems that not only our traditional system, but we all know how mixing, but also somewhat at the fringe, especially in the primary industry of system that not being really fully analyzed, you know, from an engineering perspective. And the best example it can give is all the work that we’re doing and we did over the last 15 years, maybe 20 years at this point, dealing with the dissolution testing, which is a relatively important issue in the pharma industry because every single product that needs to be released must be tested and a lot of product must be tested in such a way as to ensure that reach some quality standards.

And one of the tests that needs to be performed is dissolution, which is the test doesn’t work requires the lot to be discarded or reprocessed, if possible. So there’s a significant amount of interest in that arena. And good thing about that is as a result, of being forced to interact with scientists that in many cases have little knowledge of the engineering and complexity of the system they’re looking at, they just use it. And so this has been actually quite an interesting combination. I learned from them and I hope they learn from me and sometimes, especially when we see and predict, in many cases, some phenomena that they not expect, or maybe they suspected that exist, they saw something funny happening to understand what really is going on. And it was very rewarding for me to hear people saying, “Oh, now this is why this happens,” because they finally understand what happens in the background that eventually will result in the experimental results that they see in the lab.

John Thomas:

You’re on to something there. I mean, they’re I’m surprised at how many biologists, trained biologists we have using M-Star.

Piero Armenante:

Really?

6:58 ish

John Thomas:

Yeah, absolutely. And it’s interesting because to your point, it’s like they know there’s this, kind of gray zone, where they understand the biology, the cell mechanics, the cell mechanisms as it whatnot, or maybe even some of the dissolution physics, but they need to be able to convert that into some actionable engineering conclusions, right? Some actual engineering operating conditions that again, you know, we as engineers operate the level of operating conditions. What is my impeller speed? What’s my impeller type? What is my clearance? What is my fill volume, etc? They operate the level of cell mechanisms and these kind of tools that you and I are both working in the same space that allow us to bridge biology with engineering operating conditions is a big value I think for some of our shared clients and community.

Piero Armenante:

I fully agree. In fact, I think that the pharma industry in this respect has changed quite a bit in the last few years. In the past, engineers were kind of confined to the role of building plants and running them in a way, but they were not necessarily involved or at least not as much as now, I should say in actually developing the process from the scale at which the biologist starts or the pharmacist or the biochemist starts, up to full development. But this has changed now. A lot of companies now have hired, I’m talking about pharma company, have hired a number a large number of engineers, including in departments that didn’t exist, quite frankly, before that.

One of my best students ever, is now working for a major pharmaceutical company. And she has been hired precisely because she needs to work out some of the modeling associated with the work that they are conducting there and especially last case facility for biological processing.

John Thomas:

She’s a great story.

Piero Armenante:

Exactly, exactly. But she came as a scientist to my lab. She went to engineering courses. You know, she was in an engineer program, after all, but she had to learn quite a bit. And now she can do experiments easily. She can do […] work, she can do CFD work. She can switch easily from one to the other.

John Thomas:

Yeah, she’s very dangerous.

Piero Armenante:

Yeah! [Laughs] And she’s actually told me that now she prefers to do computational work as opposed to experimental, which surprised me, quite frankly.

John Thomas:

So that being said, I’ve seen do you have a good track record of getting students into good spots once they graduate? And I think a lot of that, you know, the culture you’ve curated inside your research group. But for folks that are maybe coming out of the undergraduate programs, you know what is a professor like you and an advisor like you, like you mentioned you’ve had scientists, you had engineers. What are you looking for when you’re looking for somebody to eventually join a group like yours that is known for getting things done and getting people placed. What are you looking for in an application?

Piero Armenante:

Good people. People with a solid background in whatever they are doing, they’re willing to move into the area that we’re working on. You know, if they come from far away field. They will not necessarily be somebody we will choose as first choice. But if they’re at NJIT and they are already oriented themselves toward engineering aspects of some of the work they do or the studies that they plan to undertake, then they need to be solid students, well-prepared in whatever they need or they’re doing.

And then I think again, within limits, we can train them. Of course, with the help of courses they need to take. And then working on the problems that we currently work on and of course, they can bring their own expertise. OK, so I’m not saying that that has to be only one way street. It’s a two way exchange, at least in some cases, which is, I think, quite beneficial. I think there’s now more talking between different disciplines than it used to be. But this still needs to be completed as a cycle, and I’m not sure if will ever be completed. So I like to interact with people. I work with microbiologists, chemists, pharmacists and I always enjoy the experience.

Although at the beginning, I felt that I knew everything. I knew it all because I was an engineer I could put equations together. I could assemble quantitative information. But then I became very humble and I learned that there’s a lot of stuff that I really don’t know. […]

So anyway, going back to what you were saying, obviously to work, you know, in the field and working in mixing, sooner or later, people have to acquire some basic skills. And some of the skills are primarily engineering skills, math skills and also modeling skills. But I would also say, I’m not sure how to say this properly, but there is intention and ability to get their hands dirty. OK. To work with systems in which they don’t just to look at in front of a screen, but that actually requires their involvement at a physical level, such people climbing stairs or plumbing system just to be able to align things properly.

John Thomas:

Right.

Piero Armenante:

With all the frustration that come with any real system in many situations, the experiment itself is the quote unquote easy part. It’s the setting up, which is troublesome. And to get everything the way we want, especially now that we can work more and more with small equipment in which the proper alignment of this stealthy small equipment in front of a particle […] may completely alter the dynamics of the system. So we need to be super careful in making sure that everything is perfectly center, that the laser is shining exactly in the middle of the vessel. That’s what we want you to look at and things of that nature that you know, the system may require much less attention, but especially as more system require a great deal of attention. This willingness to go into that direction, in other words to get involved and learn and willing to learn how to deal with this kind of system, overcome all the very practical problems that occur in any kind of lab, especially engineering lab, something that is an essential requirement for people who want to work with me.

John Thomas:

I like that. So there’s kind of three threads I got from you. One, I’m less concerned about what exactly you studied as long as you studied it well and became an expert in it. I think that’s kind of cool. Two, you need to be translational. That is, bring your game, but be prepared to learn more. Three, we need tenacity, right? The ability to find the problem and being precise as it were. And I think that’s fair game, I think.

Piero Armenante:

Absolutely.

John Thomas:

Sounds very 21st century. You know.

Piero Armenante:

In general, going for your PhD is an exercise in frustration. I told the students ahead of the game. So essentially, I say, you know, you bang your head against the wall 1000 times, but you keep doing it until you’re able to crack the wall, so to speak, and be able to make a dent. And that happens all the time. I don’t recall a single situation in which somebody started something and it went smoothly until the end without any major obstacle in between with the need to be overcome, sometimes with creative approaches.

John Thomas:

Yeah.

Piero Armenante:

Not just, you know, standard. How do I do this? How do you put the system together? Are you able to take an image from an angle that enables us to really look into a device we’re looking at precisely without putting it in such a place that the angle is not the correct point? So these are very practical issues, but they need to be addressed.

John Thomas:

Yeah. You said, what is an exercise in – ? What did you call getting a Ph.D?

Piero Armenante:

Exercise in frustration.

John Thomas:

Yeah, I think that also describes running a software company. That is also an exercise in frustration every day.

Piero Armenante:

And that’s why you need tenacity to be able to overcome it and eventually succeed.

John Thomas:

It’s a good life skill. So what sort of innovations do you think are still needed from, you know, those of us in the software development, in the modeling space? What kind of things are you looking to be served up to you as you kind of survey this integration between experiment simulation and industrial need? Are there any kind of missing links, black holes, you know, missing puzzle pieces that the software developers need to serve up to you to make you more efficient and productive in your tasks?

Piero Armenante:

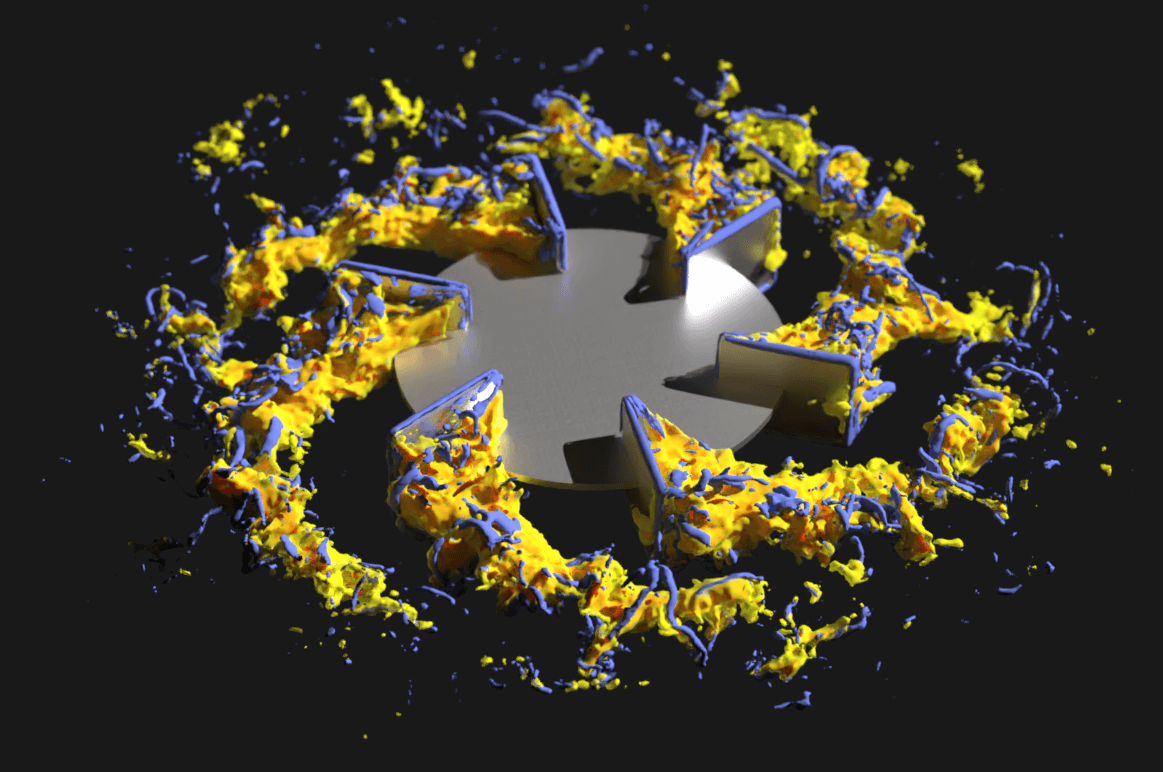

Well, that’s a very good question. Very difficult to answer. As I already mentioned at the beginning, I typically start with an appreciation for the reality of whatever it is that I’m looking at. So what I mean by that is by, if I can, performing experiments that try to orient me in the right direction and see what is the issue that I need to tackle, what is a hand at any to do. And once I am able to understand that, and perhaps I do this with the help of preliminary experiments that help me understand, in many situations, I found that new problems to come up that I have not anticipated from an experimental perspective. And when I’m able to overcome, I can say, OK now if I want to be able to use, for example, CFD to do this, what is that I need to do to make sure that the CFD somehow gives me an approximation to reality, which is always, you know, I have a great respect for reality, okay, let me put it that way. So I mean, that’s I’ve seen beautiful spirit shattered by experiments. So I always refer to that as the gold standard unless I know that there’s some issues associated with experiments themselves. And sometimes there are, of course. […] I can see coming up with respect to CFD is the incorporation of fluid properties in a CFD, especially for fluids that tend to be not the regular non-Newtonian fluids.

John Thomas:

Right? Complex rheologies and stuff.

Piero Armenante:

Exactly. So now I appreciate it even more. Because we are working with the consumer product industry and they have all sorts of fluids, it’s really something. So they have elastic property, they have no behavior […] And these are very challenging fluids, so you won’t be able to as I said to conduct experiments requires quite a lot of effort to be able to get the right fluid, but composition, the right temperature, the right property and so on. And sometimes this becomes something you cannot really play with. You have to use whatever it is that is there. And when we then try to simulate some of these fluids, sometimes you don’t have at least the software doesn’t often, as I say, have the tools for us to look at some of the more complex properties.

John Thomas:

That’s fair game, more sophisticated, rheological models and whatnot to handle more sophisticated and complicated materials. And you know, to your point. I know exactly the types of people we are talking about. And if a company has a rheology group and has people with the job title, rheologist – look out, because they’re going to give you some wicked materials. I’ve seen this firsthand.

Piero Armenante:

These people, the people in the rheology groups, they know what they’re doing, yeah, they can really teach me a lot of stuff. And subtleties that again, I never thought about and phenomena quite frankly I have never seen. And they cannot even describe other than by observing them and not able to predict what’s going to happen. And so some of these fluids are really very complex, and therefore to try to simulate them in CFD has some of the very practical complications associated with this thing.

John Thomas:

It’s tricky.

Piero Armenante:

Exactly.

John Thomas:

The governing equations may be difficult. Is it a fluid? […] I mean, what sort of equations are we even solving?

Piero Armenante:

And maybe, you know, […] you have no variability with it as a function of time. And how do you account for that?

John Thomas:

Yeah, I like that challenge, I like the challenge of the rheology.

Piero Armenante:

Another challenge that I can see is in a way related to this. But when it comes to multiphase flow, to be able to understand the interaction we typically associate with some kind of surface development between different phases. And, for example, surface tension. I mean, how do you deal with that? Because that could be a major factor contributing to the phenomenon itself? So all this biological systems are extremely complex from a rheological perspective. You have the liquid and you have microorganisms that …

John Thomas:

Anti foam and they’re changing the surface tension like that…

Piero Armenante:

Exactly, sparging of gases that interact with you, with all the components to create bubbles of different sizes and shapes, different everything.

John Thomas:

Yeah.

Piero Armenante:

In a way it goes back to the first point I was making, which is better understanding of the rheology and some of the physical properties of the fluids involved that may impact from a practical perspective, the results of whatever people are conducting. But from a computational perspective, also the models that you need to employ to be able to predict some of these very complex phenomena. And that becomes a significant challenge because now you combine the multiphase aspects, which per say, is obviously not trivial. With the properties of multiphase systems that makes the problem quite challenging in my opinion.

John Thomas:

Yeah, it grinds the gears of a simulation pretty quick. Piero, I really appreciate you coming on here and letting us pick your brain and have this discussion today.

Piero Armenante:

Well, thank you very much. A really great opportunity to talk frankly about what’s going on and what we’re doing.

John Thomas:

Can I plan to put your LinkedIn profile contact information in the description for this podcast?

Piero Armenante:

Absolutely, please.

John Thomas:

Great. It’ll be down there for folks that want to learn more about Piero’s research and follow him directly. Piero, thanks so much for your time. We appreciate it.

Piero Armenante:

Thank you very much.

John Thomas:

And keep up the great work at this really neat interface.

Piero Armenante:

Thank you. I appreciate it.

John Thomas:

A lot of great science to be had. Thanks again.

Piero Armenante:

Thank you. Bye.

Explore the Scientific R&D Software

Explore the Scientific R&D Software